Ideas with a vision

-

- from Shaastra :: vol 04 issue 05 :: Jun 2025

Easing ECG tests, cotton farming and lab lessons.

CARDITEK MEDICAL DEVICES

Founder: Sugandhi Gopal

Year: 2017

Big idea: To monitor the heart with a device that can replace old ECG machines

As an interventional cardiologist in a career of over two decades, Sugandhi Gopal has handled reams of ECG reports. She has also seen hospital technicians struggle to correctly place suction cups on a patient's arms, legs, and chest and spread a gel over at least 12 points on the body for an ECG test. This is a 100-year-old technology, says Gopal, whereas healthcare tech has advanced significantly over the years. She wondered if some of these advances could be used in developing an ECG machine that would do away with the gel and vacuum cups.

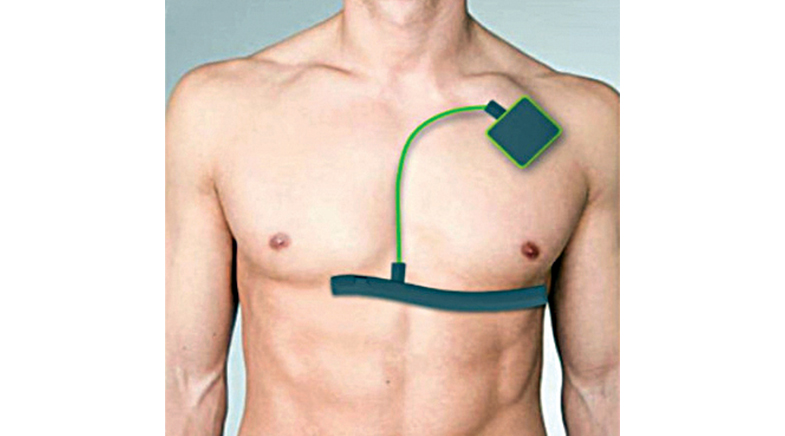

With this idea in mind, she founded Carditek Medical Devices based in Bengaluru, where she is a cardiologist at a leading hospital. Carditek's electrical cardiac bio-potential device, Sydantek, is awaiting regulatory approval before it can be commercially launched. Sydantek has a 5 cm x 5 cm patch and a strip connected through a cable. The patch is a substitute for suction cups. The device captures about three minutes' data from a patient. According to Gopal, the data is transmitted to a mobile phone via BLE (Bluetooth Low Energy) and stored in the cloud.

Whereas a regular ECG machine captures blips at 2,000 microvolts, Sydantek can capture them at 10 microvolts. The low reading is more accurate. After a cardiac episode, ECG reports do not always show abnormalities in a patient. Globally, 5% of such people die of a heart attack within a week, she says. The portable device will give readings in real time in less than a minute. "That is where it makes a difference," she says.

The device can provide insights into various parameters of the heart's functioning, including how the left side of the heart works when compared with the right side, and structural dynamic analysis. The patch and the strip are made of biocompatible materials with printed circuit boards and sensors inside. The device has been tested on nearly 20,000 patients in leading hospitals in Bengaluru and Chennai. Gopal says that Carditek will tie up with a partner to manufacture and market the device. She says the cost of an ECG test using the Carditek device will be similar to – if not lower than – current costs, while the results will be more accurate.

JYOSH AI SOLUTIONS

Founder: Sharadchandra Lohokare, Jay Lohokare and Akshay Sapkal

Year: 2020

Big idea: To use AI and robotics for enhanced farm productivity

After working in top companies for nearly 35 years, Sharadchandra Lohokare decided to strike out on his own. Lohokare, whose last stint was as the head of innovation at a leading engineering firm, was keen to use artificial intelligence (AI), computer vision, and robotics to develop solutions for agriculture and help improve efficiency and productivity. When he learnt that a U.S. company had developed a weed management solution for cotton using AI, he decided to focus on the cash crop widely cultivated in India.

Lohokare says he surveyed 600 farmers in Maharashtra's cotton-growing region of Vidarbha. The farmers spoke in favour of an automation solution for cotton cultivation, covering the entire gamut of activities and not just weed management. It led him to form JyoSH AI Solutions. It has developed five products to fully automate cotton cultivation, from sowing, weed management, and spraying pesticides and herbicides to monitoring crop health and harvesting. A low-cost electric tractor uses conventional lead-acid batteries instead of the more expensive lithium-ion batteries, and robots remove the weeds, spray the insecticides, and pluck the ripe pods. The company gets these products manufactured through partners.

The sowing machine, an electro-mechanical system, is programmed to sow the seeds at specified intervals in rows. The company, he says, uses computer vision to capture all the information on a field and, through edge computing, analyses the real-time videos that differentiate between a cotton plant and a weed, and identify harmful insects and pests. The machine also detects diseases and nutritional deficiencies in the plants. With computer vision and AI, the robot can identify and recognise only those ripe cotton pods that should be plucked. "We differentiate the ripe cotton pods for different species of cotton plants in different regions using AI," Lohokare says.

The weed-management robot, mounted on the tractor, can move in a field and detect more than 600 types of weeds. It sprays the herbicide only on weeds. The robot can pick 300 kg of cotton a day, which is equivalent to employing 10 workers, says Lohokare. "We offer end-to-end automation and mechanisation for cotton cultivation – EV tractor, seed sowing, weed management, crop health monitoring and cotton harvester," he says. The company plans to offer the services as a package to farmer-producer organisations.

CARIMO TECHNOLOGIES

Founder: Nataraj Paluri and Satyavalli Paluri

Year: 2020

Big idea: AI for engineering applications and educational kits

It started in 2010 as an informal group of instrumentation and control engineers seeking to bridge the gap between academia and industry. The group, helmed by Nataraj Paluri, who was on the faculty of the Indian Institute of Technology (IIT) Bombay, conducted courses for industries, including in the Gulf region, and handled a few projects for the Indian Railways. After he retired, Paluri, who has a Master's and a PhD from the Department of Chemical Engineering at IIT Madras, transformed the group into CARIMO Technologies, deploying artificial intelligence (AI) for engineering applications. He was joined by his wife Satyavalli, who has a Master's in Physics from IIT Madras and also worked at IIT Bombay. CARIMO is an acronym of Control, Automation, Reliability, Instrumentation, Measurement, and Optimisation. It was incubated at IIT Bombay's Society for Innovation and Entrepreneurship.

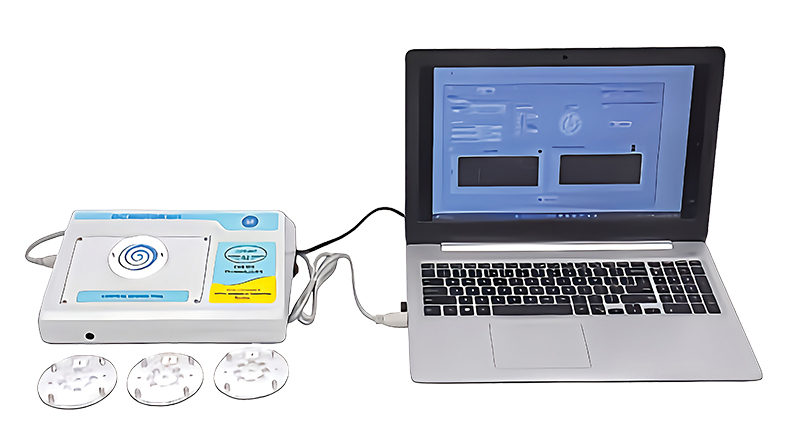

Paluri says that before he formed the company, he had developed a smart ultrasonic water meter based on projects he did for the government. He got a licence from IIT Bombay to manufacture the meters. CARIMO Technologies then developed a DC motor kit, which is used in a laboratory to conduct experiments. This enables students to see the actual working of a DC motor. The company now handles projects in the area of defence and AI. For a media company in the U.S., it does media monitoring with AI and supercomputing. "We are working mostly in machine learning, AI, computer vision, and video analytics. The DC motor kit is our bread and butter," says Paluri.

He explains that the company will help engineering and process industries address issues of predictive maintenance through solutions that have been tried out in refineries and chemical industries in the western region. The company will shortly start marketing these products. CAPMAC is a software suite developed by CARIMO that is customisable and uses AI-driven technologies to provide solutions for industries, including predictive maintenance and control systems (flow control, level control, and temperature control).

He adds that the company has added machine learning and video analytics to the CAPMAC suite for media monitoring. This product can be used to see if there are any glitches in videos that are being streamed by broadcasters. He says it will also help them monitor advertisements. CARIMO will check if an ad is of a specific duration and played at the specified time. The U.S. customer, a broadcaster, was using a legacy technology that was nearly 15 years old. CARIMO's software provides it with the latest advertisement monitoring tool, says Paluri.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH